When the students of Gyaananda School from Gurgaon walked through the gates of Rugs Creation for an industrial visit, they weren’t just entering a manufacturing facility; they were stepping into a live classroom where sustainability isn’t just talked about, it’s practised every single day.

What made this visit truly special? It wasn’t a typical factory tour where students passively observe machinery. Instead, it was a carefully designed sustainability journey that took these bright young minds through each stage of carpet manufacturing, showing them exactly how a responsible business operates in today’s world.

Let’s walk through their journey, step by step.

Table of Contents

ToggleStudent Arrival & Introduction

The day began with a warm welcome and an important message: You are the future of India, and understanding how businesses can operate sustainably is crucial for the world you’ll inherit.

The students arrived with notebooks, cameras, and most importantly questions. Lots of questions. The Rugs Creation team immediately appreciated their intelligence, curiosity, and environmental awareness. These weren’t just students on a casual trip; they were young change-makers eager to understand how industry and sustainability can work together.

The teachers accompanying them deserved equal praise. It’s clear that Gyaananda School doesn’t just teach from textbooks; they prepare students to engage with real-world challenges.

The Yarn Inward Section

The first stop was the Yarn Inward Department, and this is where students got their first lesson in organized, responsible manufacturing.

Here’s what they learned:

- How yarn is stored in a controlled environment to maintain quality

- The importance of proper handling damaged yarn means wasted resources

- Complete traceability, knowing where each batch of yarn comes from

Students observed workers meticulously cataloguing and storing different types of yarn. They learned that sustainable manufacturing begins with respecting your raw materials.

Quality & Lab Testing Department

Next came a visit to the Quality Department, where every batch of yarn undergoes careful testing before it can be used in production.

The students watched as lab technicians tested yarn for:

- Strength: Can it withstand the weaving process and years of use?

- Durability: Will the final product last, or will it need replacement quickly?

- Compliance: Does it meet international sustainability standards?

This was an eye-opener. Many students hadn’t considered that quality control is actually a sustainability practice. A product that lasts 10 years is far more sustainable than one that needs replacement every year, regardless of how it’s made.

The lab visit taught them that sustainability isn’t just about using “green” materials; it’s about creating products that don’t need to be replaced frequently.

Sustainable and Recycled Yarns

Then came the part that really got students excited: seeing sustainable and recycled yarns in action.

The team explained how recycled yarns are created from:

- Post-consumer plastic bottles

- Recycled textile waste

- Organic and natural fibers

Students learned three crucial benefits:

- Reduces waste: Giving new life to materials that would otherwise end up in landfills

- Lowers environmental impact: Less demand for virgin materials means less resource extraction

- Promotes circular economy: Keeping materials in use for as long as possible

One student excitedly calculated, “If one rug uses yarn from 50 plastic bottles, and you make thousands of rugs, that’s millions of bottles not in our oceans!”

This is where abstract concepts like “circular economy” became real and tangible for these young minds.

Rugs & Carpets Manufacturing Process

This was perhaps the most fascinating part of the journey. Students witnessed how yarns transform into beautiful rugs and carpets using both traditional craftsmanship and modern technology:

Machine Techniques:

- VDW (Van de Wiele) Machines: High-precision weaving for complex patterns

- Circular Knitted Machines: Creating seamless, durable carpets

Traditional Techniques:

- Handloom: Traditional weaving methods passed down through generations

- Punja Loom: A specialized technique for specific rug types

- Handwoven: Artisan-crafted pieces, each unique

Students were amazed at the diversity. Some had assumed that “sustainable” meant “only handmade, but they learned that both machine-made and handmade processes have their place. It’s about using the right method for the right product, minimising waste, and respecting both tradition and efficiency.

Watching skilled artisans work alongside modern machinery was a powerful lesson: progress doesn’t mean abandoning heritage.

The Zero Liquid Discharge System

If there was one part of the visit that left students truly impressed, it was this: the Zero Liquid Discharge (ZLD) system.

Here’s what happens:

- Water is used in the carpet washing and dyeing process

- Instead of being discarded, it’s treated and reused multiple times

- Finally, it’s converted into vapor, leaving absolutely no liquid waste

Zero. Liquid. Discharge.

Students from Gurgaon, living in a water-stressed region, immediately understood the significance. One student shared that their own home faces water shortages during summer. Seeing an industrial facility use water this responsibly was inspiring.

“How much water do you save?” asked another student. The answer: thousands of litres every single day.

This wasn’t just an environmental practice; it was a necessity, a responsibility, and a model for how industry should operate india with limited water resources.

Renewable Energy Sources

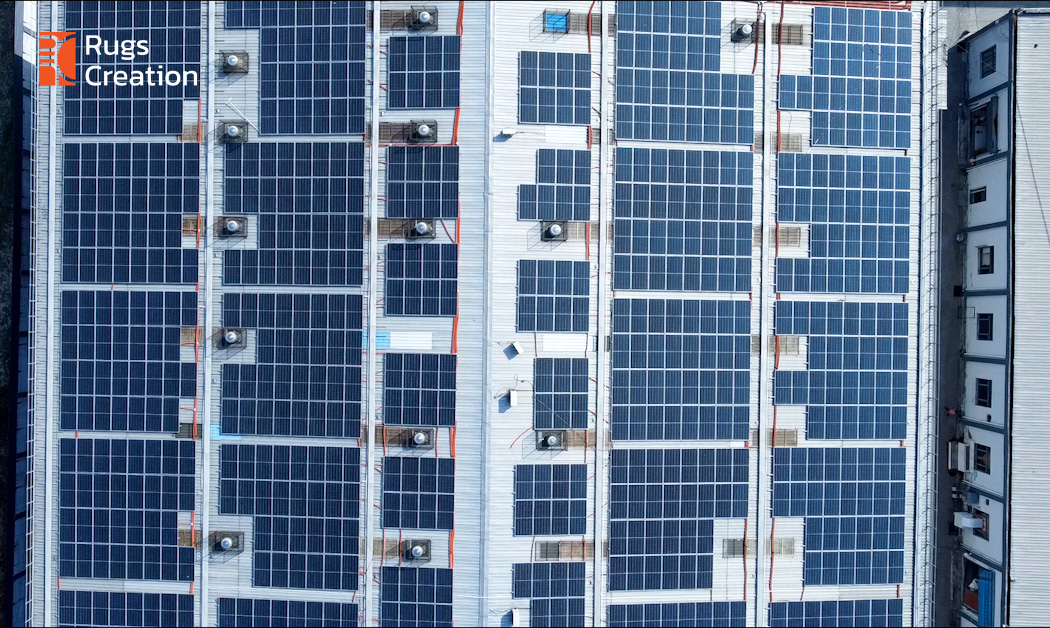

The next revelation: much of the facility’s operations are powered by solar energy.

Students walked to the rooftop to see the solar panel installations. The team explained:

- Significant reduction in carbon footprint

- Less dependency on coal-based electricity

- Long-term cost savings that make business sense

The message was clear: renewable energy isn’t just good for the planet; it’s good for business.

Interaction with Department Experts

Throughout the visit, students didn’t just observe they were engaged. Department heads and workers from various sections took time to answer questions, share their experiences, and discuss:

- Daily challenges in maintaining sustainability standards

- Career opportunities in the textile industry

- How workers feel about working for an environmentally responsible company

- The training and skills required for different roles

One worker shared how proud he felt knowing that his work contributes to reducing environmental impact. For students considering future careers, these real conversations were invaluable. They learned that sustainability isn’t just a policy decision made in boardrooms; it’s implemented daily by dedicated work at every level

CEO Interaction & Future Vision

When the conversation turned to the future, the CEO’s vision painted an ambitious yet grounded picture of what lies ahead. By 2027, the company is committed to reaching 80% renewable energy usage across all operations – a milestone that reflects their serious commitment to environmental stewardship. But the transformation goes deeper than energy alone. Complete supply chain transparency sits at the heart of their roadmap, ensuring that every thread, every process, and every partner meets the same rigorous standards they’ve set for themselves.

But perhaps the most important message was this: “You students asking these questions today means the next generation of consumers will demand sustainability. That will drive change faster than any policy.

You’re the Catalyst for Change

To the bright students of Gyaananda School: you asked the right questions. You showed genuine concern for the planet. You understood that every product has a story of resources used, people involved, and environmental impact created.

Take this learning forward. When you shop, ask: How was this made? Is it sustainable? Will it last? Your questions will push businesses to do better. The educators at Gyaananda School deserve recognition for organizing experiences that go beyond textbooks. By facilitating this visit, you’ve shown students that learning about sustainability isn’t just about reading statistics.It’s about seeing responsible practices in action.

Final Thoughts

This wasn’t just an industrial visit. It was a sustainability journey that showed young minds that a better future is possible and it’s already being built by businesses that care.

From the yarn inward section to the CEO’s office, from the lab testing department to the solar panels on the roof, every step reinforced one message: sustainability isn’t just good for the planet; it’s good for business, good for workers, and essential for the future.

If more schools organized such visits, if more businesses opened their doors to student interactions, and if more young people asked tough questions about how products are made, imagine the change we could create together.

Here’s to curious students, committed educators, responsible businesses, and a sustainable future that’s within our reach.